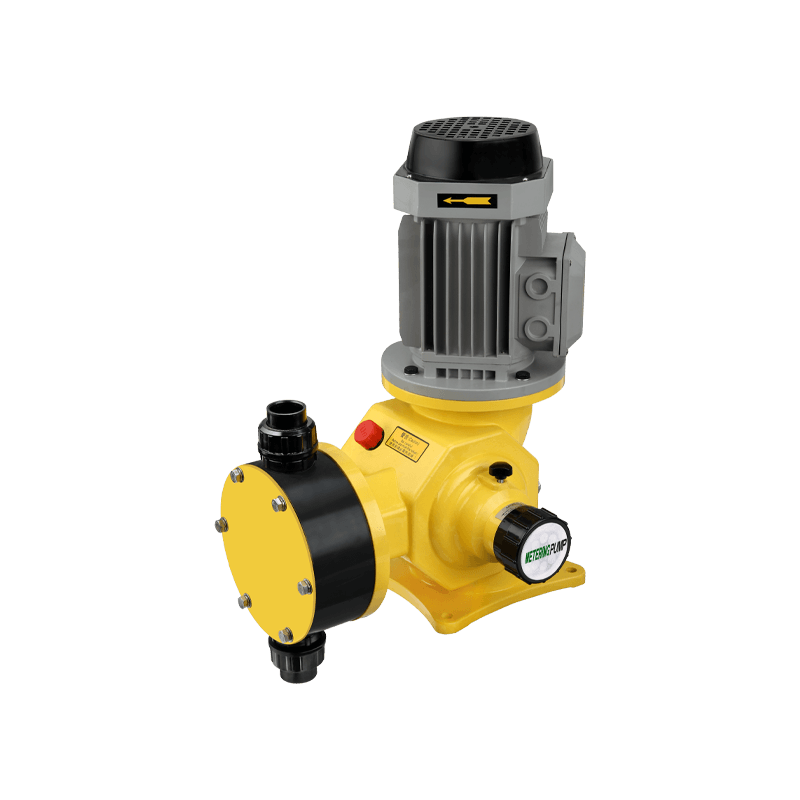

Are you looking for a reliable, economical pumping solution? Are your current pumps not providing the answers to your needs? Mechanical diaphragm metering pumps offer an efficient and cost-effective way of tackling various fluid transfer applications. From wastewater treatment plants to agricultural irrigation systems, these precision instruments provide reliable results in even inhospitable conditions. In this blog post, we will explore how mechanical diaphragm metering pumps can be used in different applications and discuss why they are becoming increasingly popular among engineers today. Let’s get started!

1.The Working Principle of Mechanical Diaphragm Metering Pumps

Mechanical diaphragm metering pumps have revolutionized the way fluids are dosed in industries. By using the alternating back-and-forth motion of a diaphragm, these pumps can repetitively deliver precise amounts of fluids. The design principle behind such pumps is quite simple – they utilize the backflow prevention valve present in each diaphragm. This ensures neither air nor fluid escapes and the correct amount of fluid is dosed. Additionally, mechanical diaphragm metering pumps can operate with low pulsation, making them ideal for use in applications that require a consistent flow rate. Overall, it is this pump's combination of mechanical force and accurate measuring abilities that set it apart from other industrial pumps.

2.Advantages of Using Diaphragm Pumps in Industrial Applications

Diaphragm pumps are a type of positive displacement pump that are widely used in industrial applications due to their numerous advantages. One major advantage of diaphragm pumps is their ability to handle a wide range of fluids, including highly viscous and abrasive liquids, without compromising performance or efficiency. Another benefit of diaphragm pumps is their ability to operate efficiently at a wide range of pressures and flow rates, making them suitable for a variety of applications. Additionally, diaphragm pumps are highly reliable, require minimal maintenance and are easy to operate, making them ideal for use in many industrial environments. Overall, diaphragm pumps are a versatile and effective solution for a wide range of pumping applications in the industrial sector.

3.Key Features That Enhance the Performance of Mechanical Diaphragm Pumps

Mechanical diaphragm pumps are essential tools for liquid handling, and their performance is critical to maintaining efficient industrial processes. Understanding the key features that can enhance their performance can help industries select the right pump to meet their needs. These features include the materials used to construct the pump, valve configuration, and diaphragm design. Materials such as stainless steel, polypropylene, and PVDF are popular for their resistance to chemical corrosion, while valve configurations can either increase or reduce flow resistance. A diaphragm's design influences its ability to handle abrasive or viscous fluids, determine the level of chemical resistance, and dictate its lifespan. By paying attention to these key features, industries can invest in reliable mechanical diaphragm pumps that offer optimal performance and longevity.

Understanding the working principle of mechanical diaphragm metering pumps, the advantages they offer in industrial applications, and the key features that enhance their performance are critical in deciding which pump best suits your particular needs. Diaphragm pumps offer many benefits over other types of fluid-handling equipment. They can be used for long-term applications as well as short-term solutions and are an ideal choice for industries requiring accurate metering with minimal maintenance. If you're considering using a diaphragm pump for your industrial application, take the time to research different models and figure out what will work best for you - you won't regret it! Make sure to also consider cost-saving measures like using nonmetallic components or employing spares efficiency strategies to get the most out of your equipment. Moreover, don’t shy away from reaching out to experts or even mechanics who have experience working with these types of pumps to ensure you make an informed decision. Now that you understand all the components involved in mechanical diaphragm metering pumps, why not contact one of our experts today and see how we can help you meet your requirements?